Handles are more than just simple grips; they play a pivotal role in the usability, ergonomics, and safety of equipment across a wide range of industries. From industrial machinery to medical devices, custom-shaped handles are designed to meet specific application needs, providing comfort, control, and precision.

Importance of Custom-Shaped Handles

Enhancing Ergonomics: One of the primary benefits of custom-shaped handles is improved ergonomics. Ergonomically designed handles reduce strain on the user by aligning with the natural shape and movements of the hand. In applications where equipment is used for extended periods, such as in manufacturing or healthcare settings, ergonomically shaped handles can significantly reduce fatigue and prevent injuries like repetitive strain disorders.

Improving Control and Precision: In many specific applications, such as precision tools or medical instruments, the shape and design of the handle directly influence the user's control over the equipment. Custom-shaped handles allow for enhanced grip, reducing slippage and ensuring that operators can perform their tasks with accuracy. A well-designed handle ensures that the user can apply the right amount of force or torque without unnecessary effort.

Meeting Application-Specific Requirements: Each industry or application has unique requirements for equipment handles. Whether it's a specific size, texture, or material, custom-shaped handles are tailored to the particular demands of the job. For example, handles used in outdoor equipment may need to be designed for wet or cold conditions, while handles for medical devices may require easy sterilization and anti-bacterial materials. Customization ensures that the handle is perfectly suited to its working environment.

Factors to Consider When Designing Custom-Shaped Handles

Material Selection: The material of the handle is a critical factor in its design, influencing everything from durability to user comfort. Different applications require different material properties.

Handle Shape and Design: The shape of the handle is paramount to its functionality and comfort. A handle that is too large or too small can lead to discomfort and strain. Custom size ensures a perfect fit, whether the handle is designed for general use or a specific demographic.

Environmental Conditions: Custom-shaped handles must be designed with the intended environment in mind. Handles used in extreme temperatures, outdoor conditions, or environments with exposure to chemicals or moisture need to be durable and resistant to degradation.

Safety Considerations: In many applications, safety is a paramount concern. Handles are often designed with features that reduce the risk of injury to the user. For example, Handles with non-slip surfaces are essential in wet or greasy environments to prevent accidents.

Industries That Benefit from Custom-Shaped Handles

Medical and Healthcare: Custom-shaped handles are vital in the medical field, where precision and control are essential. Surgeons, nurses, and technicians require ergonomic handles for instruments that are used for delicate procedures. Customization allows for tools that are comfortable to hold and easy to maneuver, reducing hand fatigue during lengthy procedures.

Industrial and Manufacturing: In industrial settings, workers often use heavy equipment for long periods. Custom-shaped handles on machinery or tools can reduce strain and improve efficiency. Ergonomically designed handles help reduce workplace injuries by improving posture and providing better grip.

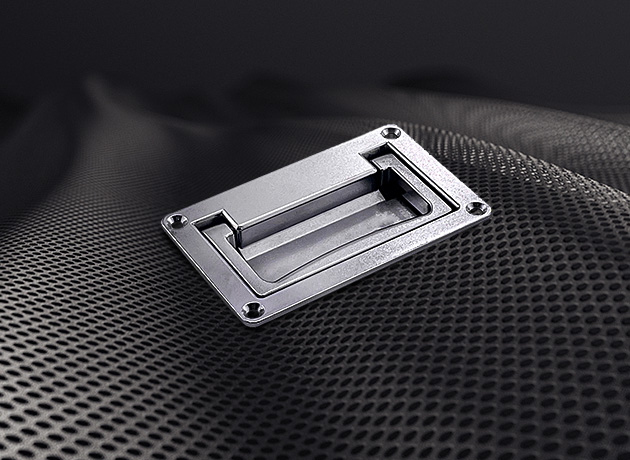

Consumer Products and Furniture: Custom handles are also popular in the consumer goods industry. From kitchen tools to furniture, handle design influences both aesthetics and usability. Custom-shaped handles on cabinets, drawers, and appliances offer an added element of comfort and visual appeal.

Sports and Fitness Equipment: Sports equipment such as tennis racquets, golf clubs, and fitness machines often require specialized handles designed for performance and comfort. Custom handles in these applications ensure that athletes can maintain their grip and control during intense activities, optimizing performance.

Conclusion

Custom-shaped handles play a crucial role in enhancing the functionality, comfort, and safety of equipment in various industries. Whether it's improving ergonomics in medical devices, providing durability in industrial settings, or offering style and usability in consumer products, the right handle design is key. By carefully considering material selection, environmental factors, and ergonomic needs, custom-shaped handles can be tailored to meet the specific demands of any application, ensuring optimal performance and user satisfaction.

Elevate your equipment's performance, safety, and user experience with Manywell's exceptional range of equipment handles. Browse our Equipment Handles Collection to see if there's an option that's right for you. Of course, we offer custom-shaped handles for specific applications to meet your requirements.