Stainless steel machine handles are a vital component in various industrial, medical, and manufacturing environments, providing operators with control, precision, and safety while using equipment. The choice of handle can significantly affect both the performance of machinery and the ergonomics of the operator. Stainless steel is highly valued in machine handle manufacturing due to its strength, corrosion resistance, and durability.

Why Stainless Steel for Machine Handles?

Corrosion Resistance: Stainless steel is known for its resistance to rust and corrosion, making it ideal for environments where moisture, chemicals, or exposure to harsh weather conditions are prevalent. This makes stainless steel handles a durable option for both indoor and outdoor applications.

Strength and Durability: Handles made from stainless steel are robust and capable of withstanding heavy-duty use. They are ideal for machinery in industries such as manufacturing, construction, or heavy equipment, where the handle needs to endure repeated stress and high loads without deforming.

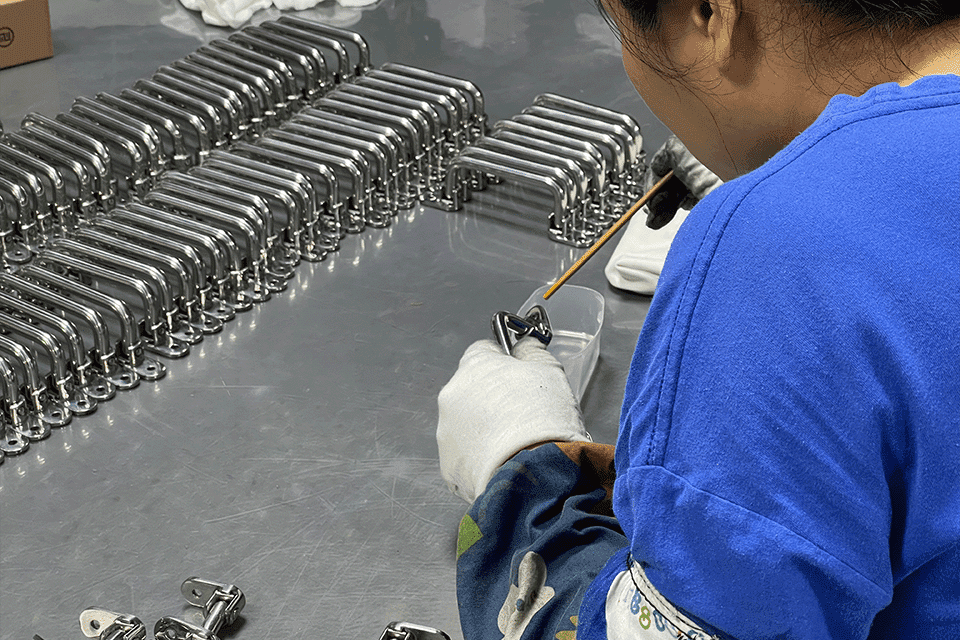

Hygienic Properties: In applications where hygiene is critical, such as in food processing or medical equipment, stainless steel is a preferred material due to its easy-to-clean surface and resistance to bacterial growth. Stainless steel handles are smooth and non-porous, making them ideal for sterile environments.

Easy-to-clean handles for hygiene

Types of Stainless Steel Machine Handles

Fixed Handles

Fixed handles, also known as stationary handles, are permanently attached to machinery and provide a stable grip for operating equipment. These handles do not move or adjust, making them ideal for applications where a consistent and firm grip is required.

Applications:

Lathes and milling machines: Handles on these machines are designed for steady operation and need to endure consistent force.

Heavy-duty machinery: In industrial environments, fixed handles provide a secure point for lifting or maneuvering equipment.

Folding Handles

Folding handles are designed for compactness and can be folded out of the way when not in use. These handles are typically used in equipment where space is limited, or portability is a priority. Folding handles are commonly found in machinery that requires frequent transport or storage.

Applications:

Portable machines and tools: Ideal for compact industrial machines or portable equipment that need to be stored in tight spaces.

Inspection equipment: Used on machinery that needs to be frequently moved or adjusted.

T-Handles

T-handles are a specific type of handle shaped like the letter "T," providing leverage for turning or applying torque. These handles are commonly used in machinery where precision and torque control are necessary. The design allows users to grip both ends of the handle, distributing force evenly and making it easier to turn or operate heavy-duty machinery.

Applications:

Machine tools: T-handles are often found on equipment that requires precise adjustments, such as tightening or loosening bolts or adjusting mechanical components.

Valves and control equipment: Ideal for machinery with components that need to be manually opened or closed with controlled force.

Crank Handles

Crank handles consist of a lever arm with a rotating handle, often used to turn components or mechanisms in machines. These handles are typically found in machines that require manual adjustments, such as adjusting machine settings or moving parts into place. The crank design allows for efficient rotary motion, making it easy to apply rotational force.

Applications:

Machinery adjustment: Crank handles are used to adjust the positioning of machine parts or to set precise measurements in industrial equipment.

Medical equipment: Crank handles are often used in hospital beds or diagnostic machines to allow easy manual adjustments.

Pull Handles

Pull handles are long handles designed for pulling or opening components, such as access panels, doors, or drawers on industrial equipment. They are simple yet durable, providing a reliable grip for moving large or heavy items. Pull handles are commonly used in environments where equipment needs frequent access for maintenance or operational adjustments.

Applications:

Heavy machinery: Pull handles on access panels for machinery provide easy access for maintenance or inspections.

Storage units: Used for industrial storage units or toolboxes that require a firm grip to open.

Lever Handles

Lever handles are commonly used for opening, closing, or controlling machinery functions. They provide the operator with leverage, making it easy to move or shift components within machines. Lever handles are often designed to allow for quick and precise movements, making them ideal for equipment requiring frequent control adjustments.

Applications:

Control panels: Used on machinery control panels to adjust settings or activate components.

Valve operations: Ideal for controlling the flow of liquids or gases in industrial equipment.

Conclusion

Stainless steel machine handles are a crucial component in industrial machinery, offering strength, durability, and resistance to harsh environments. From fixed and folding handles to T-handles and crank handles, each type of handle serves specific purposes, enabling operators to control machinery effectively and safely. By carefully considering the application, environment, and ergonomic requirements, businesses can select the appropriate stainless steel handle to improve the performance and longevity of their equipment.

Manywell, a leading manufacturer of high-quality equipment device handles, offers a comprehensive range of ergonomic handles for tools designed to improve the user experience and ensure optimal performance across various industries. We offer custom-shaped handles for specific applications to meet your requirements. Browse our Equipment Handle page to see if there's an option that's right for you.